The benchmark in terms of economic efficiency and flexibility for small workpiece diameters

Flexible processing of circular hollow sheet metal parts with diameters larger than 60 mm

A sound concept for the future

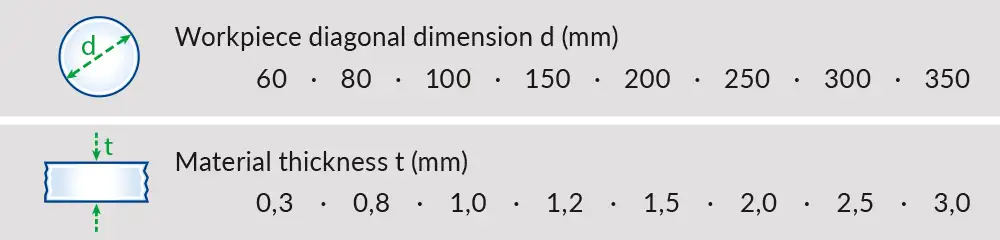

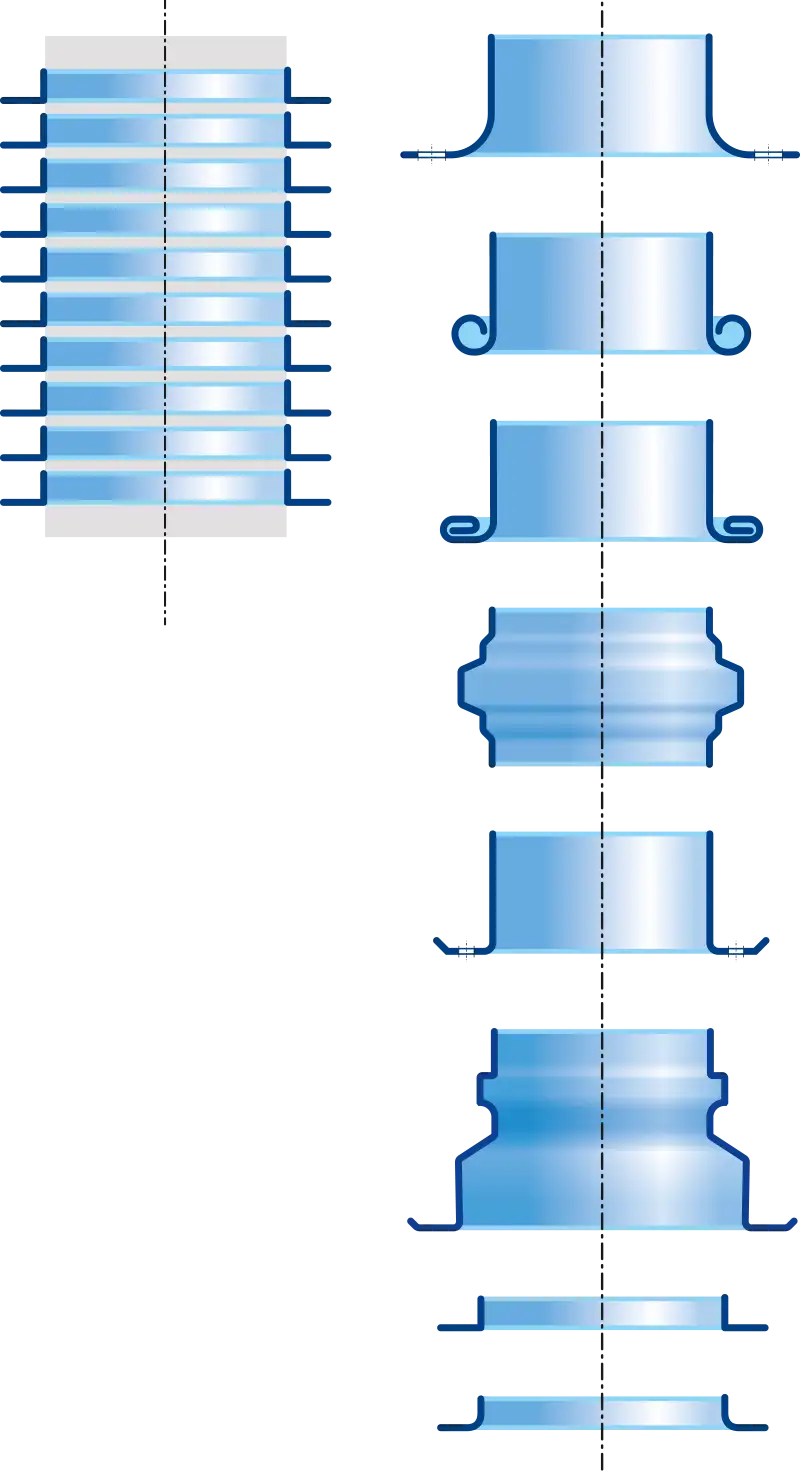

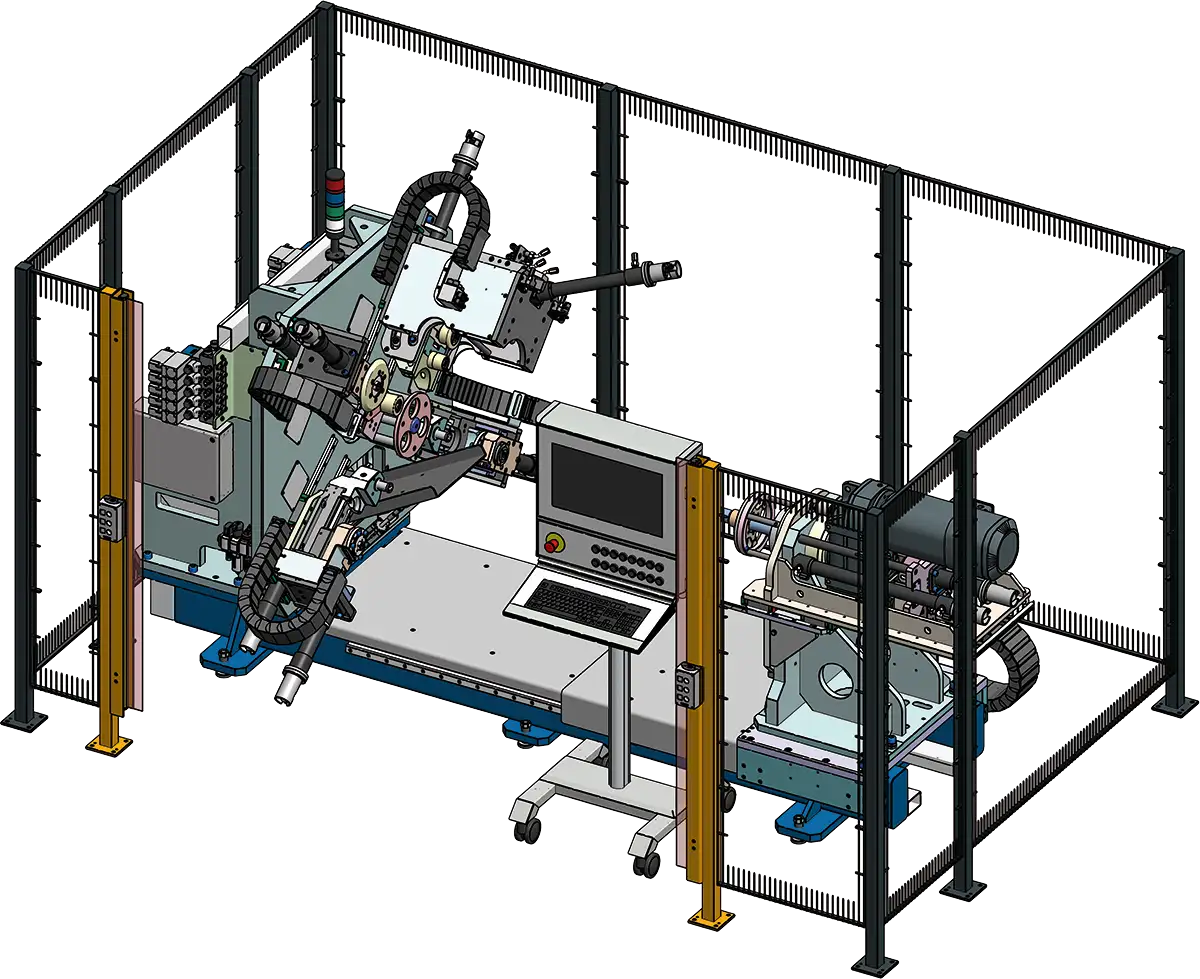

With the FLEXFORMER SD, KURTH + HEUSER presents an innovative machine series for edge processing of cylindrical hollow sheet metal parts with small diameter. The special feature is the fully flexible programming of all axes for the forming processes. Thanks to the freely programmable adjustment of the workpiece holder and counterholder, the FLEXFORMER SD actuators can be utilised effectively and flexibly. Highly dynamic, even for demanding operations, they guarantee high quality and repeat accuracy. In contrast to conventional machine concepts, the FLEXFORMER SD enables several processes to be performed in a single clamping operation, and that with workpiece diameters starting from D60.

Highlights

- Servo-hydraulic or servo-electric axes: robust and accurate

- Processing using up to four actuators

- 80 % less setup time and setup errors

- Flexible programming

- Perfect repeat accuracy

- Ring production from tubes

The product line

The FLEXFORMER SD line is a modular system consisting of basic machines using different actuators selected according to workpiece dimensions, materials and processing tasks. The most diverse forming operations are executed in a single fixture. The assembly group for clamping allows the series production of, e.g., flange rings from a single tube with only very little effort.

Programming

Motions and processing steps of the FLEXFORMER SD machines are parameterised in their logic sequence. Individual axes, interpolation, motion profile and force control are easily selected via drop-down menus. This significantly reduces the time that operators need to familiarise themselves with the machine. The machines can also be programmed offline.

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information